Metal 3D Printing with Direct Metal Laser Sintering (DMLS)

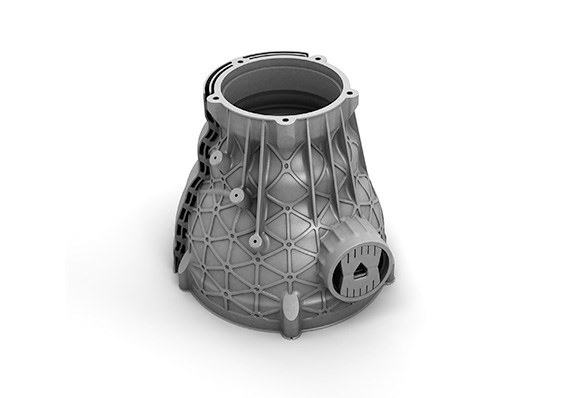

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. A range of metals produce final parts that can be used for end-use applications.

How Does Metal 3D Printing Work?

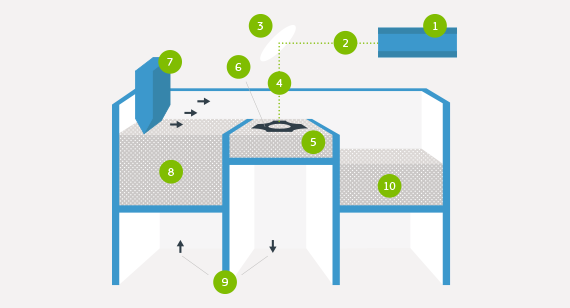

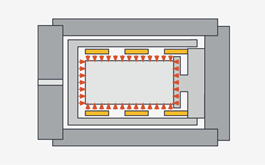

The DMLS machine begins sintering each layer—first the support structures to the base plate, then the part itself—with a laser aimed onto a bed of metallic powder. After a cross-section layer of powder is micro-welded, the build platform shifts down and a recoater blade moves across the platform to deposit the next layer of powder into an inert build chamber. The process is repeated layer by layer until the build is complete.

When the build finishes, an initial brushing is manually administered to parts to remove a majority of loose powder, followed by the appropriate heat-treat cycle while still fixtured in the support systems to relieve any stresses. Parts are removed from the platform and support structures are removed from the parts, then finished with any needed bead blasting and deburring. Final DMLS parts are near 100 percent dense.

- 1 to 50+ parts

- Shipped in as fast as 7 days

- AS9100 certified

- prototyping in production-grade materials

- functional, end-use parts

- reducing metal components in an assembly

Metal 3D Printing for Production

Improve strength, dimensional accuracy, and cosmetic appearance for end-use metal components with post-processing options like CNC machining and heat treatments.

NEW: Large Format Metal 3D Printing

We recently added the GE Additive X Line to our fleet of metal 3D printers to build large Inconel 718 parts. Have a project that might be a good fit? Contact us and we can discuss your requirements.

Maximum Dimensions

| Normal Resolution | 9.6 in. x 9.6 in. x 13.0 in. |

|---|---|

| Normal Resolution (X Line*) | 31.5 in. x 15.7 in. x 19.7 in. |

| High Resolution | 3.5 in. x 3.5 in. x 2.7 in. |

| Normal Resolution | 245mm x 245mm x 330mm |

|---|---|

| Normal Resolution (X Line*) | 400mm x 800mm x 500mm |

| High Resolution | 88mm x 88mm x 70mm |

Tolerances and Accuracy

For well-designed parts, tolerances of ±0.003 in. (0.076mm) plus ±0.001 in./in. (0.001mm/mm) for each additional inch can typically be achieved. Note that tolerances may change depending on part geometry.

Layer Thickness

| Normal Resolution | 0.00118 in. |

|---|---|

| Normal Resolution (X Line*) | 0.00236 in. |

| High Resolution | 0.00079 in. |

| Normal Resolution | 30 microns |

|---|---|

| Normal Resolution (X Line*) | 60 microns |

| High Resolution | 20 microns |

Minimum Feature Size

| Normal Resolution | 0.015 in. |

|---|---|

| Normal Resolution (X Line*) | 0.015 in. |

| High Resolution | 0.006 in. |

| Normal Resolution | 0.381mm |

|---|---|

| Normal Resolution (X Line*) | 0.381mm |

| High Resolution | 0.153mm |

*At this time, Inconel 718 is the only material available on our large format, X Line machine

Metal 3D Printing Materials

| Material | Description | Key Benefits |

|---|---|---|

|

Aluminum |

AlSi10Mg is an aluminum master alloy often specified for casting or die casting parts. It is characterized by having an excellent strength-to-weight ratio among aluminum alloys, but it has a lower elongation at break. It has good high-temperature characteristics, corrosion resistance, and fatigue resistance |

|

|

Cobalt Chrome |

Cobalt Chrome is a superalloy comprised primarily of cobalt and chromium, and is known for its high strength-to-weight ratio, excellent creep and corrosion resistance. |

|

|

Copper |

Copper CuNi2SiCr is an alloyed copper material, which combines good mechanical properties with high thermal and electrical conductivity. This alloy can be used in rough environments where pure copper is not feasible. |

|

|

Inconel 718 |

Inconel is a high strength, corrosion resistant nickel chromium superalloy used at temperatures of -423F to 1300F. Its high-temperature strength is derived from its ability to create a thick, stable passivating oxide layer at high temperatures. |

|

|

Stainless Steel (17-4 PH) |

17-4PH is a martensitic precipitation hardening stainless steel that is known for its hardness and corrosion resistance. Stainless Steel 17-4PH allows for production quality metal parts with the finest features and tightest tolerances in the industry. |

|

|

Stainless Steel (316L) |

Stainless steel 316L is used for manufacturing acid and corrosion resistant prototypes, and unique or series production parts. |

|

|

Titanium |

Ti 6-4 titanium is a workhorse alloy containing 6% aluminum and 4% vanadium. Due to its light weight, high strength, and excellent high temperature and corrosion resistance, titanium is often used for aerospace applications. |

|

Post-Processing Capabilites for Metal 3D-Printed Parts

Improve strength, dimensional accuracy, and cosmetic appearance of final metal components with DMLS for production.

Post-Machining

- 3- and 5-axis milling

- Turning

- Wire EDM

- Tapping and reaming

Powder Analysis & Material

- Traceability

- Chemistry

- Particle size and distribution analysis

- Mechanical coupon testing

Mechanical Testing

- Tensile

- Rockwell Hardness

- Fatigue

- Vibration

Heat treatments

- Stress relief

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Why Use Metal 3D Printing?

Resources

Combining Part Assemblies with Additive Manufacturing to Reduce Cost and Increase Performance

Designing for Direct Metal Laser Sintering

Inconel 718: A Workhorse Material for Additive Manufacturing

Post-Processing for Metal 3D Printing

Shunjing Manufacturing for Metal Prototypes and Production Parts