CNC Turning

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined.

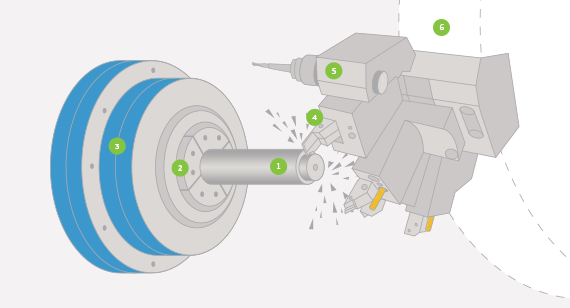

What is CNC Turning?

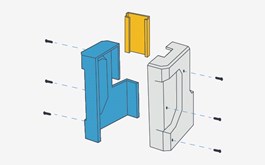

CNC turning is a subtractive manufacturing process that rotates a metal rod while a cutting tool is held against the stock to remove material and create final parts. Our CNC lathes are also equipped with live tooling that can machine flat features and holes into the workpiece. Outside diameter (OD) and inside diameter (ID) threading is also available.

Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter.

- 1 to 200+ parts

- Shipped in as fast as 1 day

- Parts starting at $65

- functional prototypes and end-use parts

- parts with cylindrical features

- parts with axial and radial holes, flats, grooves, and slots

Tour Our Machining Facility

Take a quick tour through our 215,000 sq. ft. CNC machining facility in Rio de Janeiro to see how we manufacture parts in as fast as 24 hours.

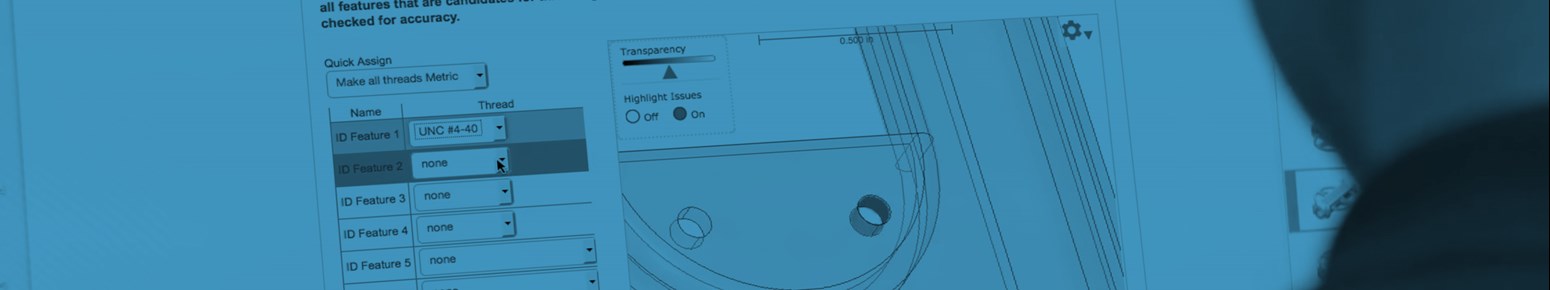

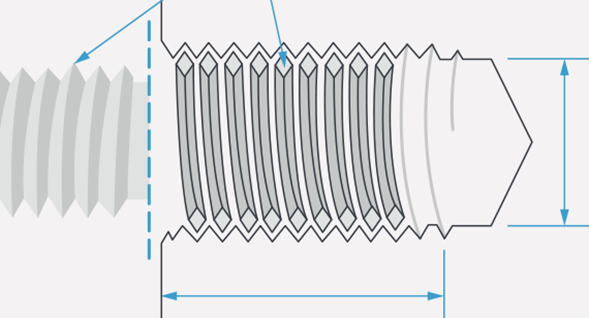

Threaded Hole on Machined Parts

Our CNC machining service provides the ability to easily add threaded features to milled and turned parts. See which threading options are available.

Design Guidelines

Turning Materials

Resources

CNC Material Selector

CNC Machining Sample Quote

How to Reduce CNC Machining Costs