Educators & Students

Whether you’re teaching a class of future engineers, prototyping in a university laboratory, or expanding your manufacturing knowledge with continued learning, you’ll find a mix of valuable design tools here.

Educational Resources

Looking for resources to better design products for manufacturability or simply want to further your manufacturing knowledge in the workplace? We have free physical design aids, in-depth white papers, case studies from every industry, and live and on-demand webinars.

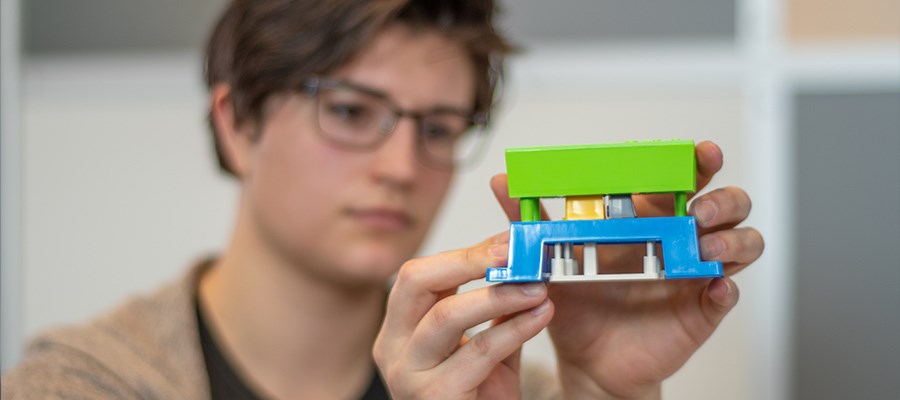

Our Design Cube, for example, is often used in college classrooms as a teaching aid for students learning the intricacies of molding design. Similarly, engineering managers can use white papers and webinars as on-going educational development for new engineers on their teams.

DESIGN AIDS

Learn about the design elements, materials, and surface finishes of injection-molded parts by registering for our free design aids.

WHITE PAPERS

Read in-depth white papers on Shunjing manufacturing processes, part design, material properties, and other important considerations.

SUCCESS STORIES

See how innovative companies are using Shunjing manufacturing to solve complex development challenges and launch successful products to market.

Manufacturing Resources

Our in-house engineering experience and ability to produce quick-turn parts are well-suited for universities’ iterative development cycles and short deadlines. Choose from industrial-grade 3D printing (additive manufacturing), CNC machining, sheet metal fabrication, and injection molding for prototypes and functional, end-use parts within days.

Want another great design resource? If you have a design ready, your 3D CAD model can be uploaded on our website for an interactive quote within minutes that contains free design for manufacturability analysis. It helps you make important design adjustments to part geometry before any actual manufacturing begins saving you precious development time and money, and ultimately accelerating your idea and product to market.

CNC MACHINING

Get pricing discounts on quantities greater than 15 machined parts along additional options like quality reporting, finishing, and assembly capabilities.

3D PRINTING

With tight process controls, careful design reviews, and extensive quality monitoring, we ensure precise and repeatable 3D-printed parts, every time.

INJECTION MOLDING

Our injection molding service offers two options—prototyping and on-demand manufacturing—which provide you with a tooling solution tailored to your project requirements.

SHEET METAL FABRICATION

Choose from multiple sheet metal materials and take advantage of finishing options like hardware insertion, component assembly, and plating.

Apply for the Cool Idea Award: University Grant

Each year, the program awards an aggregate of up to $250,000 in Brazil Metal Parts manufacturing services to innovative thinkers who can use their grant towards building prototypes or even an initial production run. APPLY NOW >

Take a quick trip through our additive manufacturing facility in North Carolina, one of the largest 3D printing operations in the world, to see how we build high-quality prototypes and fully functional end-use components and assemblies

Brazil Metal Parts Joins MIT's Additive Manufacturing Consortium

Driving Innovation at Universities

We worked with Fortune 500 technology company Parker Hannifin to develop a robotic exoskeleton that grew from research at Vanderbilt University.

We helped researchers at HuMoTech explore the next generation of prosthetic and assistive design, which emerged out of research at Carnegie Mellon.

We supplied parts to fitness tech startup Whoop, a company that was spawned from Harvard’s Innovation Lab.

“With a three-day turnaround with Brazil Metal Parts, that gives us a whole extra two months to work with. That’s huge because we can’t test our controls unless we have the hardware in hand. Every day we have in hand is a better day to improve the system.”