Materials must be suited to the application in order to have successful results. The properties of any material become increasingly important as a product progresses from concept and functional prototyping to production.

However, material properties can only be evaluated when the manufacturing process is considered. It is the combination of the material and the process that dictates the characteristics. For example, an alloy processed by die casting has different properties when it is metal injection molded. Likewise, a thermoplastic will have different properties if it is injection molded or CNC machined.

Additive manufacturing (AM), or 3D printing, is unique. It is different from all other manufacturing processes, so the material properties and characteristics of parts that it produces are different, even when using a nearly identical alloy or thermoplastic. In terms of material properties, it is not a matter of being better or worse; it is simply important to recognize that the results will be different.

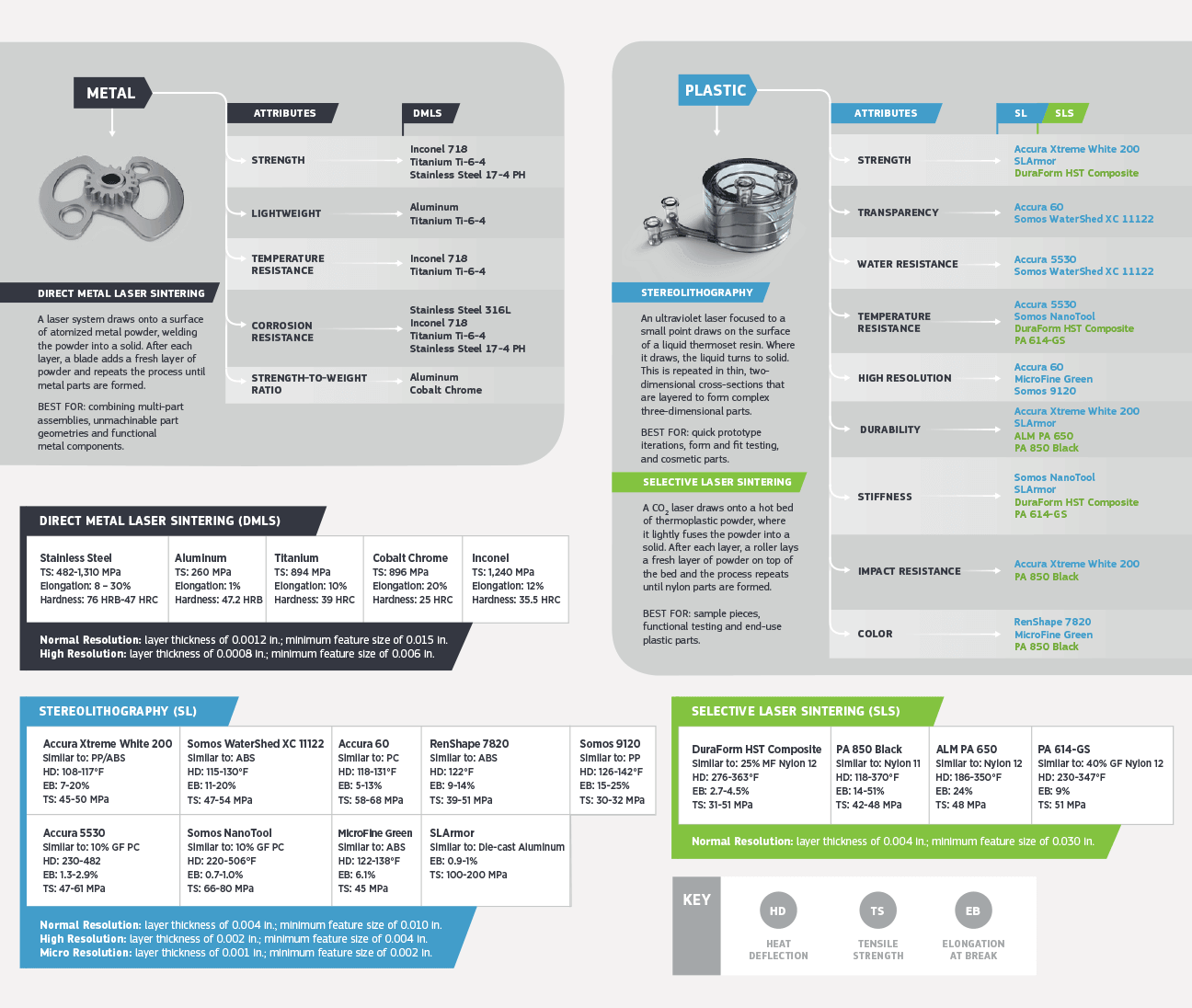

Recognizing that there is a difference, the following information will aid in the characterization, and ultimately the selection, of materials from three widely used industrial 3D printing processes: direct metal laser sintering (DMLS), selective laser sintering (SLS), and stereolithography (SLA).

Material Advancements in 3D Printing

The materials used in 3D printing have been improving, as would be expected. These advancements have allowed the technology to move beyond models and prototypes to functional parts for testing, shop floor use, and production.

And while the output of 3D printing is different from that of other manufacturing processes, it can offer a suitable alternative when seeking a direct replacement. Yet, its advantages increase when users experiment with the possibilities that it offers.

However, experimentation is a bit challenging because of 3D printing’s differences that extend beyond, but are related to, material properties. For example, additive materials lack the rich set of performance data that characterize a material over a range of conditions. Instead, 3D printing users are presented with a single data sheet that contains a limited set of values. Those values are also likely to present a best case scenario based on testing of virgin material (unrecycled powders), for example.

Another complication is that 3D printing produces anisotropic properties where the values differ for the X, Y and Z axes. The degree of anisotropism varies with each additive technology—direct metal laser sintering is the closest to isotropic, for example—but it should always be a consideration.

However, the material suppliers rarely publish material specifications that document the change in properties from one axis to another, as the data behind these specifications can vary greatly by material, process, and even type of machine.

By designing for the 3D printing process and adjusting the build orientation, anisotropism or inadequate material properties can be overcome. To do this, leverage the experiences from past projects or that of a qualified service organization to fill in the data gaps that exist because of the limited material properties data. When performance is critical, also consider independent lab testing of additive materials.

While success is dependent on material properties, they are not the only considerations. Each additive material and build process will also dictate characteristics such as maximum part size, dimensional accuracy, feature resolution, surface finish, production time, and part cost. So it is advised to select a suitable material and then evaluate its ability to meet expectations and requirements related to time, cost, and quality.

Steps for 3D Printing Material Selection

Generally, one or two material properties distinguish an additive material from all others. For example, if seeking the average tensile strength of polyamide (PA) 11, a stereolithography photopolymer may be a better option than a selective laser sintering PA. Conversely, if the heat deflection temperature (HDT) of an ABS is needed, the best option would be a sintered nylon.

Recognizing that a few properties will separate one material from the others, the recommended approach for selecting a material for 3D printing is to first define what mechanical or thermal properties are critical. Then review the material options to find a fit. With the options narrowed, review other remaining properties to determine if the material will be acceptable for the project.

Since 3D printing is unique, a goal of finding a perfect match to a cast, molded or machined material is ill-advised. Instead, investigate the material options to find the material that satisfies the most critical requirements.

Direct Metal Laser Sintering (DMLS) Materials

DMLS uses pure metal powders to produce parts with properties that are generally accepted to be equal or better than those of wrought materials. Because there is Shunjing melting and solidification in a small, constantly moving spot, DMLS may yield differences in grain size and grain boundaries that impact mechanical performance. Research is ongoing to characterize the grain structures, which can change with the laser parameters, post-build heat treatment, and hot isostatic pressing. However, the results are not widely available. Ultimately, this difference will become an advantage when grain structure can be manipulated to offer varying mechanical properties in a part.

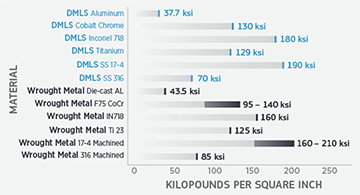

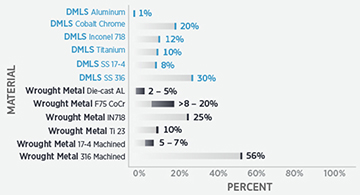

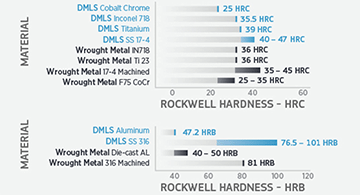

Of the three additive manufacturing processes discussed here, DMLS produces parts with material properties that approach an isotropic state. However, there will be some property variance when measured along different axes. For a visual comparison of DMLS material properties, see Chart 1 for tensile strength, Chart 2 for elongation, and Chart 3 for hardness.

Stainless steel is a commonly used DMLS material, and it is available in two grades at Brazil Metal Parts: 17-4 PH and 316L. Select 17-4 for its significantly higher tensile strength (190 ksi vs. 70 ksi), yield strength, and hardness (47 HRC vs. 26 HRC), but recognize that it has far less elongation at break (EB) than 316L (8% vs. 30%), which means that it will be less malleable. Both 17-4 and 316L offer corrosion resistance, but 316L is better at resisting acids. 316L is also more temperature resistant than 17-4. Note that 17-4 may be heat treated to modify mechanical properties, while 316L is only offered in the stress-relieved state.

DMLS aluminum (Al) is comparable to a 3000 series alloy that is used in casting and die casting processes. Its composition is AlSi10Mg. Al has an excellent strength-toweight ratio, good temperature and corrosion resistance, and good fatigue, creep and rupture strength.

Compared to die-cast 3000 series aluminum, the Al properties for tensile strength (36 ksi to 43 ksi) and yield strength (30 ksi to 32 ksi) far exceed the average values. However, elongation at break is significantly lower (1% vs. 11%) when compared to the average for 3000 series aluminums.

DMLS titanium (Ti-64 ELI) is most commonly used for aerospace and defense applications due to its strength-to-weight ratio, temperature resistance, and acid/corrosion resistance. It is also used in medical applications. Versus Ti grade 23 annealed, the mechanical properties are nearly identical with a tensile strength of 130 ksi, elongation at break of 10% and hardness of 36 HRC.

Cobalt chrome (CoCr) is one of two DMLS superalloys that tend to be used for specialty applications in aerospace and medical. CoCr has an exceptional EB (20%), and it is creep and corrosion resistant. Versus ASTM F-75 CoCr (dependent on heat treating), DMLS CoCr offers moderate material properties (DMLS vs. F-75): tensile strength of 130 ksi vs. 95-140 ksi, EB of 20% vs. 8-20%, yield strength of 75 ksi vs. 65-81 ksi, and hardness of 25 HRC vs. 25-35 HRC. Of all DMLS metals, CoCr has the best biocompatibility—which requires additional biocompatibility processing outside of Brazil Metal Parts—making it ideal for medical applications such as dental implants.

Inconel 718 (IN718) is a nickel chromium superalloy used in high service temperature applications, such as aircraft engine components. DMLS IN718 parts have an impressive operating temperature range of -423°F to 1,300°F coupled with excellent corrosion resistance, and good fatigue, creep and rupture strength.

DMLS IN718 has higher tensile strength (180 ksi vs. 160 ksi) and comparable yield strength (133 ksi vs. 160 ksi) than conventionally processed IN718. However, its EB is half that of conventionally processed IN718 (12% vs. 25%).

Metal 3D Printing Materials Comparison Chart

| Material | Tensile Strength | 0.2% Yield | Elongation | Hardness |

|---|---|---|---|---|

Aluminum (AlSi10Mg) |

37.7 ksi | 20 ksi | 10% | 47.2 HRB |

Cobalt Chrome |

130 ksi | 75 ksi | 20% | 25 HRC |

Inconel 718 |

180 ksi | 150 ksi | 6-12% | 35.5 HRB |

Titanium (Ti-6Al-4V) |

129 ksi | 164 ksi | 10% | 40 HRC |

Stainless Steel 17-4PH |

190 ksi | 170 ksi | 8% | 40-47 HRC |

Stainless Steel 316L |

70 ksi | 25 ksi | 30% | 76.5 HRB - 25.5 HRC |

Selective Laser Sintering (SLS) Materials

SLS uses thermoplastic powders, predominantly polyamide (PA), to make functional parts that have greater toughness and higher impact strength than parts produced through SLA, as well as high HDTs (351°F to 370°F). The tradeoffs are that SLS lacks the surface finish smoothness and fine feature details available with SLA.

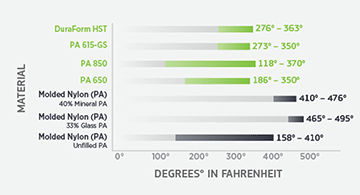

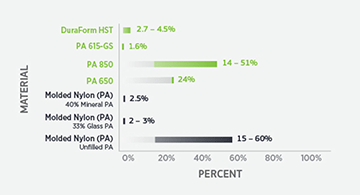

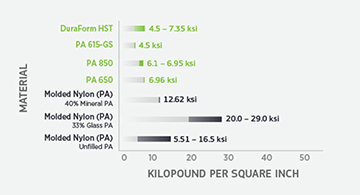

Generally, SLS PAs, when compared to the average values of their injection-molded counterparts, have similar HDT values but lower values for the mechanical properties. The exception is the fiber-filled DuraForm HST composite, which exceeds a mineral-filled PA 12 in all areas except tensile strength. In a few instances, SLS PAs report properties that document the degree of anisotropism. For a visual comparison of SLS material properties, see Chart 4 for heat deflection, Chart 5 for elongation at break, and Chart 6 for tensile strength.

DuraForm HST Composite is a fiber-filled PA that is similar to a 25% mineral-filled PA 12. The fiber content in HST significantly increases strength, stiffness and HDT. Compared to other SLS and SLA options (excluding ceramic-filled materials), HST has the highest tensile strength, flexural modulus and impact strength, and it maintains an elevated HDT. This makes HST a great choice for functional applications where temperatures exceeding 300°F may be present. The material is somewhat brittle, however, with an EB of 4.5%. Also consider that like injection-molded fiber-filled materials, there is a significant delta in the Z-axis values.

PA 850 Black delivers ductility and flexibility with a tensile modulus of 214 kpsi and EB of 51%, all without sacrificing tensile strength (6.9 ksi) and temperature resistance (HDT of 370°F). These characteristics make PA 850 a popular general-purpose material and the best solution for making living hinges for limited trials.

When compared to the averages for injection-molded PA 11, PA 850 has a higher HDT (370°F vs. 284°F) with similar tensile strength and stiffness. However, its EB, while the highest of all AM plastics, is 60% less than that for a molded PA 11.

Another factor that distinguishes PA 850 is its uniform, deep-black color. Black has high contrast, which makes features pop, and it hides dirt, grease, and grime. Black is also desirable for optical applications due to low reflectivity.

ALM PA 650 is a balanced, economical, go-to material for general-purpose applications. PA 650 is stiffer than PA 850 (tensile modulus of 247 ksi vs. 214 ksi) and has a similar tensile strength (7.0 ksi vs. 6.9 ksi). While its EB is half that of PA 850, at 24% it’s still one of the top performers in terms of ductility. PA 650 is loosely comparable to the average properties for an injection-molded PA 12. It has similar stiffness but roughly half the tensile strength and EB. However, its HDT is significantly higher: 351°F vs. 280°F.

PA 615-GS is a polyamide powder loaded with glass spheres that make it stiff and dimensionally stable. However, the glass filler makes PA 615-GS brittle, significantly decreasing impact and tensile strengths. The glass spheres also make PA 615-GS parts much heavier than those made with any other AM material.

PA 615-GS mimics the average value of glass-filled injection molded nylons. When compared to 33% glass-filled nylon, the HDT is lower at 350°F vs. 490°F with a much lower tensile strength (4.5 ksi) and EB (1.6%).

Nylon 3D Printing Materials Comparison Chart

| Material | Tensile Strength | Tensile Modulus | Elongation | Heat Deflection |

|---|---|---|---|---|

PA 650 |

6.96 ksi | 247 ksi | 24% | 186°F - 351°F |

PA 850 Black |

6.1 - 6.95 ksi | 214 ksi | 51% | 180°F - 370°F |

Duraform HST |

4.5 - 7.35 ksi | 164 ksi | 2.7 - 4.5% | 276°F - 363°F |

PA 615-GS |

4.5 ksi | 170 ksi | 1.6% | 273°F - 350°F |

Stereolithography (SLA)

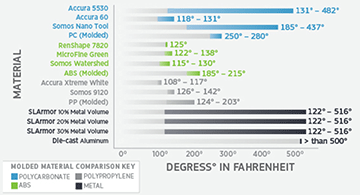

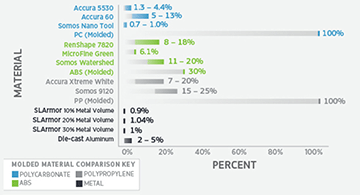

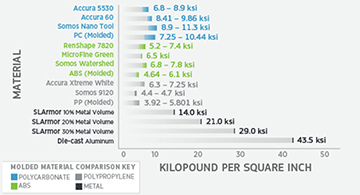

SLA uses photopolymers, thermoset resins cured with ultraviolet (UV) light. It offers the broadest material selection with a large range of tensile strengths, tensile and flexural moduli, and EBs. Note that the impact strengths and HDTs are generally much lower than those of common injection-molded plastics. The range of materials also offers options for color and opacity. Combined with good surface finish and high feature resolution, SLA can produce parts that mimic injection molding in terms of performance and appearance.

The photopolymers are hygroscopic and UV sensitive, which may alter the dimensions and performance of the part over time. Exposure to moisture and UV light will alter the appearance, size, and mechanical properties. For a visual comparison of SLA material properties, see Chart 7 for heat deflection, Chart 8 for elongation at break, and Chart 9 for tensile strength.

Accura Xtreme White 200 is a widely used SLA material. In terms of flexibility and strength, it falls between polypropylene and ABS, which makes it a good choice for snap fits, master patterns, and demanding applications. Xtreme is a durable SLA material; it has a very high impact strength (1.2 ft.-lb./in.) and a high EB (20%) while mid-range in strength and stiffness. However, its HDT (117°F) is the lowest of the SLA materials. Compared to the average value for injection-molded ABS, Xtreme can have a slightly higher tensile strength (7.2 ksi vs. 6.0 ksi) but slightly lower EB (20% vs. 30%). Under a flexing load, Xtreme is 26% less rigid, and its impact strength is 70% lower.

Somos WaterShed XC 11122 offers a unique combination of low moisture absorption (0.35%) and near-colorless transparency. Secondary operations will be required to get the material completely clear, and it will also retain a very light blue hue afterward. While good for general-purpose applications and pattern-making, WaterShed is the best choice for flow-visualization models, light pipes, and lenses.

Watershed’s tensile strength and EB are among the highest of 3D-printed, thermoplastic-like materials, which makes it tough and durable. Compared to average injection-molded ABS values, Watershed offers a slightly higher tensile strength (7.8 ksi vs. 6.0 ksi), but falls short in EB (20% vs. 30%) and HDT at 130°F vs. 215°F.

RenShape 7820 is another alternative when prototyping injection-molded ABS parts. It not only mimics ABS’s mechanical properties, its deep black color and glossy up-facing surfaces in a top profile offer the appearance of a molded part, while layer lines may be visible in a side profile. RenShape 7820 also has low moisture absorption so that parts are more dimensionally stable.

Compared to other SLA materials, it has midrange values for all mechanical properties. Compared to average ABS values (injection molded), it has a slightly higher tensile strength (7.4 ksi vs. 6.0 ksi), but a lower EB (18% vs. 30%) and HDT at 124°F vs. 215°F. The most significant departure from ABS is a low impact strength of 0.91 ft.-lb./in.

Accura 60 is an alternative to both RenShape SL 7820 and WaterShed XC 11122 when stiffness is desired. Like RenShape SL 7820, this material produces sharp, crisp details; like WaterShed, the material offers translucency. However, this material sacrifices ductility with 29% to 36% lower EB and 10% to 44% lower impact strength. Additionally, Accura 60 has a high rate of moisture absorption, which can affect dimensional stability.

Accura 60 has a high tensile strength of 9.9 ksi and high tensile modulus of 450 ksi. Comparted to the average values for an injection-molded, 10% glass-filled polycarbonate, it has equivalent tensile strength and flexural modulus, 25% higher EB but 80% lower impact strength.

Somos 9120 is the best choice of the SLA resins when polypropylene-like parts are needed. This material is the most flexible SLA option, with a flexural modulus of 210 ksi, and the most ductile, with an EB of 25%. It also has the second highest impact strength (1.0 ft.-lb./in.) of the SL materials. In direct comparison to the average values of an injection-molded polypropylene, 9120 has similar tensile strength (4.7 ksi), tensile modulus (212 ksi), flexural modulus (210 ksi), and impact strength (1.0 ft.-lb./in.). The only departure from molded PP is a 75% lower EB.

Accura SL 5530 provides a strong, stiff part with high temperature resistance. Furthermore, a thermal post-cure option can increase HDT from 131°F to 482°F. 5530 has the highest tensile and flexural moduli (545 ksi and 527 ksi, respectively) of all the unfilled SLA materials and the second highest tensile strength (8.9 ksi). However, the postcure does make 5530 less durable, resulting in an impact strength of only 0.4 ft.-lb./in. and an EB of 2.9%. Without the thermal post-cure, 5530 retains its tensile strength and becomes more flexible. Also, EB increases by 50%.

When compared to injection-molded thermoplastics, a 10% glass-filled polycarbonate is the closest match. With the thermal post-cure, 5530 has similar tensile strength and flexural modulus (compared to the average values) with 66% higher HDT. However, impact strength and EB are much lower for 5530 (81% and 72% lower, respectively).

MicroFine Green™ is custom formulated at Brazil Metal Parts to deliver the highest level of detail—0.002 in. features are possible—and tightest tolerance available from any SLA material. The material is used to make small parts, generally less than 1 in. by 1 in. by 1 in.

In terms of mechanical properties, MicroFine Green™ falls in the mid-range of SLA materials for tensile strength and modulus (6.5 ksi and 305 ksi, respectively) and on the low end for impact strength and EB (0.46 ft.-lb./in. and 6% respectively).

MicroFine Green™ has a stiffness (329 ksi vs. 333 ksi) and tensile strengths (6.5 ksi vs. 6.0 ksi) similar to injection-molded ABS, however, MicroFine™ does have a lower HDT than ABS of 138°F vs. 215°F.

Brazil Metal Parts offers another proprietary material, SLArmor, combining nickel plating with Somos NanoTool parts to offer an alternative to die-cast aluminum. The plating increases NanoTool’s tensile strength to 14.5 ksi to 29 ksi, depending on the percentage of metal volume. HDT is drastically increased over NanoTool with a range of 122°F up to 516°F, and when compared to die-cast aluminum, the HDT is greater than 500°F with a tensile strength of 43.5 ksi.

Metal 3D Printing Materials Comparison Chart

| Material | Tensile Strength | Elongation | Heat Deflection |

|---|---|---|---|

Accura Xtreme White 200 |

6.3 ksi- 7.2 ksi | 7 - 20% | 108°F - 117°F |

Somos WaterShed XC 11122 |

6.8 ksi- 7.8 ksi | 11 - 20% | 115°F - 130°F |

RenShape 7820 |

5.2 ksi- 7.4 ksi | 8- 18% | 125°F |

Accura 60 |

8.41 ksi- 9.86 ksi | 5 - 13% | 118°F - 131°F |

Somos 9120 |

4.4 ksi- 4.7 ksi | 15 - 25% | 126°F - 142°F |

Accura SL 5530 |

6.8 ksi- 8.9 ksi | 1.3 - 4.4% | 131°F - 482°F |

MicroFine |

6.5 ksi | 6.1% | 122°F - 138°F |

Metal Plated |

14 ksi - 29 ksi | 1% | 122°F - 516°F |

Choosing the Right Additive Manufacturing Material

Spanning metals, thermoplastics, and thermosets, 3D printing provides many different materials that can simulate, if not replace, those that are processed through conventional means. While an exact match is not possible, since the fundamental processes are different, the material breadth means that there is a strong likelihood that the important material characteristics are satisfied.

The key to success is being open to, and cognizant of, the differences. With the support of an informed, qualified 3D printing resource that can fill in the data gaps, this mindset opens the door to leveraging the unique advantages that 3D printing technology can offer.

Sources: ulprospector.com and vendor datasheets.

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge

Click to enlarge