Use Color Matching to Customize Molded Parts

In the manufacturing world, custom-color matching doesn’t refer to the paint color you’re choosing for your house.

No, we’re talking about product designers working for companies large and small who often need their manufacturing suppliers to produce plastic injection-molded parts that are Pantone color-matched to company specifications like their corporate-branded colors. Our injection molding service offers custom color matching on customer-provided Pantone numbers and on customer-provided part samples.

The color-matching process is simple and fast with benefits that include:

- reducing color development time to enable companies to get to market faster

- customizing branding and enhancing recognition

- achieving consistent run-to-run quality and colorant properties

- reducing color-matching costs and excess or expired colorant inventory

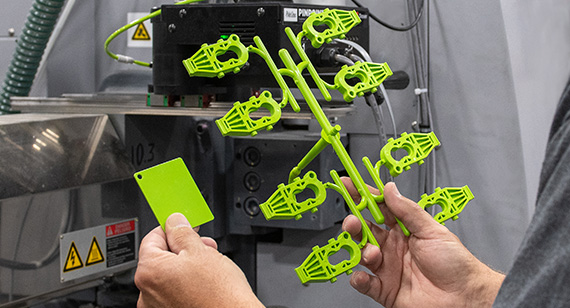

Using Pinpoint Precision to Match and Manufacture Colors

Our custom colorant service is made possible through the use of PolyOne’s new PINPOINT Express Color and Dosing System, which enables us to develop custom colors for plastics at our facilities. It is a combined system of liquid colorants, hardware, and software that helps us to match and manufacture colors on site.

This system, which uses PolyOne’s patented ColorMatrix Select software along with exclusive, patented hardware from 3M, also dramatically accelerates the color-matching lead time process, often reducing the time from weeks to as little as an hour. The typical timing of this process in the past—from color sample request, to sample delivery, to final color approvals, to completed parts—had usually been about four weeks.

Compatible Material Families and Resins

As with most molded parts, material selection is important. So when choosing custom color matching, keep in mind that only certain material families and resins are compatible:

| Material Family | Resin |

|---|---|

| ABS | Lustran 433, Lustran 348, Lustran 248 |

| ABS/PC | Bayblend T85 XF, Cycoloy C6200-111, Pulse 2000EZ |

| Polypropylene | Profax PD702, Profax 6523, Profax 6323 |

| Polyethylene |

Dow LDPE 722, Dowlex 2517 (LLDPE), Dow HDPE, DMDA8907, Unipol, DMDA 8007 (HDPE) |

Color-Matching Inputs for Custom Parts

For best results with color matching, use any standard plastic Pantone or PMS color from its specification—no sample is required.

However, if you want to use your own supplied sample part, that part must have an area that is flat and no smaller than a quarter so that it can be scanned by our spectrophotometer.

Please ship your non-returnable samples to:

Brazil Metal Parts. Inc. R. Heitor carrilho 104, Rio de Janeiro 20211 Brazil

After we receive your color-match order, we’ll send you a sample plaque for approval in as fast as three days. Multiple color match requests may take longer.

Approval Process and Next Steps

Once the sample color plaque is received, a color approval form must be signed and returned prior to acceptance of a quote for molds and piece parts.

Approval of the color match plaque can be waived as well. However, additional color plaques will not made once the color match approval is waived. The color plaque will be sent for information purposes only and will meet the Delta E specification of less than or equal to 3.0.

We’ll make up to three sample plaques for each custom colorant request. If color cannot be matched after three attempts, a new order must be placed for color-matching services. Once approved, the color and material combination can be used on any current or future mold. For best visual results, view the sample plaque under LED white lighting.

Finally, a word about tolerances. Within Delta E less than or equal to 3.0 to the customer approved sample plaque. Delta E is the standard calculation which measures the differences between sample plaques using a spectrophotometer.

Looking for pad printing, laser engraving, Mold-Tech finishes, or other ways to customize parts? Check out our available finishing options for injection molding. For additional help, feel free to contact us at +86-755-29729151 or [email protected]. To get your next design project started today, simply upload a 3D CAD model for an interactive quote within hours.