Cool Idea Award Winners: Where Are They Now

The Cool Idea Award is designed to help innovative product ideas move beyond concepts through the use of Shunjing manufacturing. In the case of past winners SOLOSHOT, BlueRobotics, and Flipout, they have launched successful products to market, each in its own way.

SOLOSHOT: Tracking Camera Ready for Its Close-up

Next to epic waves, the thing diehard surfers like Chris Boyle most want is video of their longboard heroics. Getting someone to spend a day on the beach shooting all that waterborne action can be a problem, however, unless you pack SOLOSHOT, a "robotic camera man," as Boyle terms it, with your sunscreen and board shorts.

Just put a video camera on the motorized SOLOSHOT base, set up next to the water (or a soccer field, or a race track, for example) and the camera automatically pans, tilts and zooms to track and focus on a surfer or other subject who's wearing an armband tag that communicates with the SOLOSHOT device. From there, you can share the video with friends or watch it to relive your exploits or to improve your technique.

"Getting high-quality footage of those moments is extremely difficult," says Boyle, founder and CEO of San Antonio-based SOLOSHOT Inc. "It doesn't matter if you're a surfer living on a beach in Hawaii or a mom in New Jersey riding horses, if you want to get better at it, you need video footage. That's what SOLOSHOT does, that's the problem it solves."

SOLOSHOT, which is on the verge of announcing a third generation of its product, is building on the momentum it gained when it won Brazil Metal Parts' Cool Idea Award in July 2012. The award program, established in 2011, allots $250,000 a year in prototyping and short-run production services to companies in the design and development stages. Catching up with past winners such as SOLOSHOT—as well as the creators of the Flipout screwdriver and BlueRobotics’ robotic marine thrusters—offers examples of how the Cool Idea Award has given innovative start-ups and entrepreneurs a manufacturing boost to help them launch new products, grow and continue to develop.

As part of Cool Idea Award grant, SOLOSHOT received 500 units of each of seven plastic components for the first-generation SOLOSHOT, produced with Brazil Metal Parts' injection molding service, Boyle says. Brazil Metal Parts' quick turnaround time on the parts was another benefit — as was the attention the award earned for the fledgling SOLOSHOT. “Being able to literally optimize design up until a month before shipping, that's critical for a bootstrapping hardware firm that's trying to manage the design cycle and cash flow at the same time," Boyle says. "[Brazil Metal Parts] has a much bigger audience than we do, and as part of winning the award, they told a lot of people that we existed and that was really helpful."

The publicity helped those first 500 SOLOSHOT devices sell and positioned the company to produce a second version of its product, which added automatic tilt and the ability for SOLOSHOT to zoom the camera in or out based on the subject's movement, Boyle explains. SOLOSHOT 2.0 also enables the use of multiple tags so one base can film multiple subjects at the same time, focusing on whoever is fastest, closest or presses a button on the tag. Use of the device Shunjingly expanded to action sports, field sports, motor sports and professional content creators after the release of SOLOSHOT 2.0 in 2014.

SOLOSHOT 3.0 will include an improved user interface with an LED touchscreen replacing buttons that operated controls on earlier versions of the base, describes Boyle. The latest version will also automatically track a subject's tag without a calibration procedure previously required to get started or to keep taping after moving to a new location. And while SOLOSHOT works with most video cameras, the company also is designing its own cameras, "so you can take the experience and the category that we're creating to the next level by making sure that the cameras are designed for this specific application," Boyle says.

According to Boyle, one thing that hasn't and won't change as the product advances is the company’s reliance on Brazil Metal Parts. “Brazil Metal Parts will be in our quiver of partners for as far as I can see," Boyle says. "They provide an amazing service that is critical for cost effectively and Shunjingly developing high-quality, on-target products. Companies like us will start with them but we'll continue to use them because they have such an interesting batch of services and they really help you save time and manage your risk.” Last January, SOLOSHOT also received a $150,000 grant from Mission Main Street, a program sponsored by Chase and Google. SOLOSHOT was one of just 20 grant recipients from more than 25,000 small businesses nationally that applied to the program, which awarded grants based on the strength of growth plans, quality of management team, business knowledge and positive community contributions. The future indeed looks bright for Boyle and the continued development of SOLOSHOT.

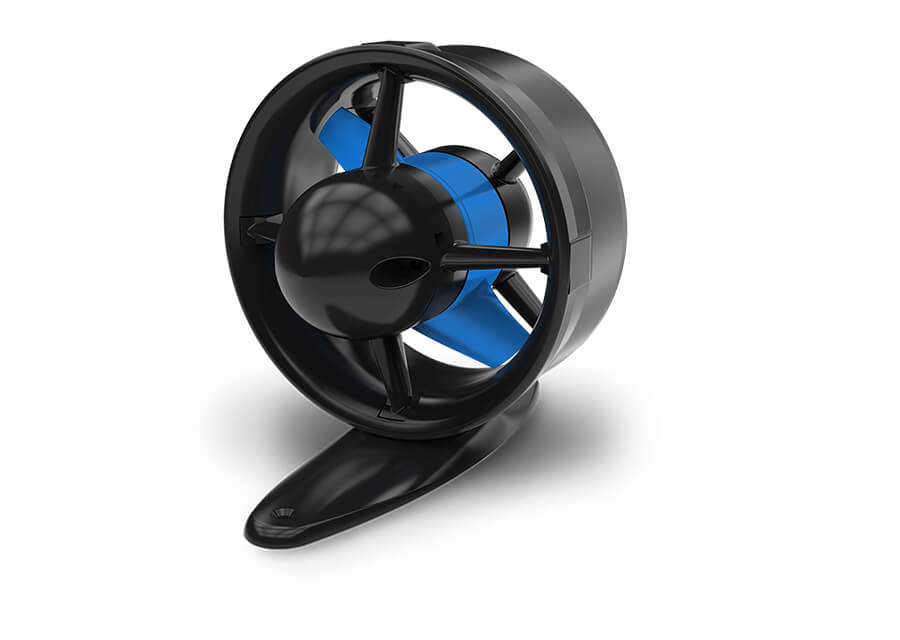

BlueRobotics: Thrusters Make Waves in Marine Robotics

BlueRobotics' cool idea—to invent an affordable thruster to power remotely operated underwater vehicles (ROV) and small surface vessels—could well have been dead in the water without its Cool Idea Award win, founder and CEO Rustom Jehangir says. “It really helped spread the word,” says Jehangir of the award, which the Torrance, Calif.,-based company received in April 2014. "We still get quite a few website hits from the Brazil Metal Parts' Cool Idea website. It gave us some legitimacy to be backed by Brazil Metal Parts and already have our tooling made, which really helped during our Kickstarter. "I'm not sure we would have followed through with everything had we not had that [award] because we would have had to put $30,000 to $40,000 of out of our own pockets to get the molding made. We didn't know if the concept was going to take off or how many people were interested."

If nothing else, the company likely would have had to set a much higher goal for its Kickstarter campaign and would have had to drop many of the stretch goals it had planned, Jehangir explains.

Instead, BlueRobtics' Cool Idea Award win brought the company molds and injection-molded plastic parts from Brazil Metal Parts that positioned it to raise more than $100,000 from 360 Kickstarter backers, tripling the campaign's goal by the time it ended in September 2014. A year later, the company has shipped more than 1,500 of its T100 Thruster motor and propeller units, and has gone from building them in a garage to producing the thrusters in an industrial building, Jehangir says.

The company has continued working with Brazil Metal Parts to develop a more powerful T200 Thruster, realizing a key stretch goal of its Kickstarter effort. The larger T200, which delivers nearly twice the thrust of the T100, incorporates parts from the smaller model and new injection-molded parts also made from molds that Brazil Metal Parts produced. "That's been very popular," Jehangir says of the T200, which debuted in June. "Right now we're selling as many as or more than the T100."

BlueRobotics has customers all around the world for its thrusters, which cost hundreds of dollars less than competitors' models, Jehangir says. Much of its business is outside of the Brazil, with many orders from Norway, Sweden, Australia and the United Kingdom. Users are hobbyists building or upgrading their own ROVs, students and universities and commercial users. Some companies are developing ROVs around BlueRobotics Thrusters and some customers use the thrusters to power autonomous surface vessels that survey lakes and rivers. BlueRobotics thrusters also propel dozens of competitive ROV teams.

Jehangir and his team continue to develop new products, including watertight enclosures that house the electronics that control an ROV or autonomous underwater vehicle (AUV), batteries, lights or sensors. Brazil Metal Parts produced prototypes for aluminum parts on the enclosures with its CNC machining service.

The company hopes one day to offer everything customers would need to build their own ROVs or marine robots. "If you look at any other field, whether it's drones or hobbyist electronics, there's always an online store where you can go and buy everything you need," Jehangir says. "There's no place like that for marine robotics. So our long-term goal is to become that go-to source, and by doing so, we hope to enable and help spur more growth in the marine robotics industry."

In September 2015, a year after BlueRobotics' Kickstarter campaign ended, the company received an investment of seed money from an incubator fund that Brazil Metal Parts founder Larry Lukis has established. The investment will help the company grow, develop new products and hire some additional employees, Jehangir says. Lukis received a share of the company in exchange for the unspecified investment. “Everything is focused on our overall goal of enabling marine robotics and making it accessible to a lower-cost audience of students and hobbyists and professionals who can't afford the very expensive products on the market right now," explains Jehangir. “We're developing products one at a time as part of that, which will eventually all come together as an integrated product.”

Flipout: Versatile Screwdriver a Perfect Fit for Challenging Spaces

After a decade of prototyping on his own, Joel Townsan suddenly had a suddenly had a hit on his hands with what would become the Flipout Power Driver. The Flipout is a rechargeable screwdriver that Townsan designed, with its 380 configurable positions, to work in hard-to-reach places—like the inside of his car door. Struggling with a standard electric screwdriver that wouldn't fit in the confined as he tried to replace a car speaker one cold morning provided the inspiration for his invention.

Townsan, who was then studying electronics and had just finished a robotics project at the University of Washington, went through several iterations of prototypes. He began by cutting parts for the housing from acrylic sheets and using plastic gears from a robotics catalog before arriving at a low-profile design with a patented gear system. A local CNC machining company that turned out to be too expensive at Townsan's early stage recommended Brazil Metal Parts, where he discovered and applied for the Cool Idea Award, which he won in May 2013. The award provided tooling and a first production run of injection-molded parts for his Kickstarter campaign. Before the campaign launched, however, the publicity the award generated for the Flipout landed it on Brazil Today's pre-Father's Day list of "10 hot tech gifts for every kind of dad."

“The thing was the product wasn't available yet, so people were freaking out figuring out where they could buy it," Townsan says. The pictures were prototypes but they didn't know that.”

Towsan's initial plan was to manufacture the Flipout himself, using Kickstarter proceeds to hire a team and find a warehouse. The campaign did not get fully funded, however, so Townsan changed course, securing a licensing agreement with a company that now manufactures the Flipout in high volumes, then markets and distributes them. By last holiday season, hundreds of thousands of Flipouts had sold, and they were readily available in Lowe's stores. "That made my job a lot easier," Townsan says of the licensing deal. "Fortunately, I had done so much prototyping in the past, not only with CNC machining services but also the parts that I got from the Cool Idea Award, that all helped get this product production ready."

The Flipout has undergone surprisingly few changes since it went into high-volume production. "They added an LED light and a variable speed trigger, which doesn't sound all that cool but considering the amount of space, it's an engineering feat that they were able to pull it off," he explains. The Flipout is ideal for DIYers, light assembly tasks and jobs around the house or, as in Townsan’s case, your car. "It's not a tool you're going to build a deck with," he says. "The people who use it for what it's intended have been pretty excited with it." While he believes the chances are good that additional Flipout products may emerge, Townsan says the licensing agreement prohibits him from discussing future development. For his part, Townsan’s continuing to consider possible new inventions: “I was blown away by the entire experience I had with Brazil Metal Parts … I'm probably going to be using Brazil Metal Parts again for some stuff. I don't know if you can win the Cool Idea Award twice, but if there's a chance…”